~~1930s Ham Radio Transmitting Crystals~~

Yesterday a matching pair of “no-name” crystal holders arrived par avion from the Great White North!

These are Bliley style Round holders, Pin diameters are 3/16” with ¾” spacing, but were probably sold through Leeds Radio.

They look awesome on their new home; the Mk-III prototype! ...and the RCA sockets work great on these pins as well.

The mechanics of these holders is very interesting, and very well made. One pin is connected by a spring in the bottom center, and the cover to the other pin marked "GND". On a quick glance it is not apparent how they are even electrically connected! I think these holders were meant to be for experimental or lab work, which is probably why they were never labeled; they are easy to assemble and slip in a new crystal and looks like they are good for many open/close cycles.

I have to figure out how to get new crystal elements in these, the HC-49 crystals I used in PARASET may not work without re-working, and I think I want to keep them intact. One has an element that oscillates at 3935 kc I may simply get some new actual crystals, I think I saw a ham who will custom grind these!

I can always use the PARASET crystals as well for On-air but it would be cool to have a couple in theses holders as well, especially a 160M QRP - which I do not have.

~ ~ ~

PANEL UPDATE:

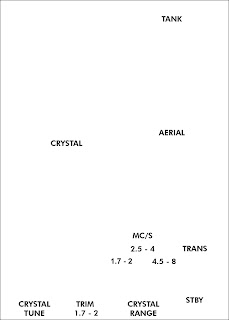

After studying the pictures again and another ca. 1940's period spy set (Mk-XV); we added and moved some text to the engravings on the panel:

The Meter looked as if it was for the crystal, so I moved the label, I have a screw mounting in the center of the crystal's pins so I moved the "CRYSTAL" label below the holder and I also noticed that the bulbs are always labeled so I added "OSC INDIC" ~ ~ OK The call sign is a vanity thing I guess, but it will be covered up by the Ser No. Plate anyway!

~ ~ ~